VIMS trains interns in oyster aquaculture

The Virginia Institute of Marine Science has begun a new program to train the skilled workers needed to advance Chesapeake Bay’s rapidly growing oyster-farming industry.

The Oyster Aquaculture Training program, or OAT, is the brainchild of professor Stan Allen, Director of the Aquaculture Genetics and Breeding Technology Center (ABC) at VIMS.

Allen established the program, which welcomed its first four trainees in April, to help provide private oyster farmers with workers who are skilled in oyster husbandry in the hatchery and field. ABC staff, principally Karen Hudson and Amanda Chesler, crafted program specifics. The program is funded by an anonymous private donor.

Allen says the program’s goal “is to provide Virginia’s expanding aquaculture industry with trained technicians using a pool of local, interested people.”

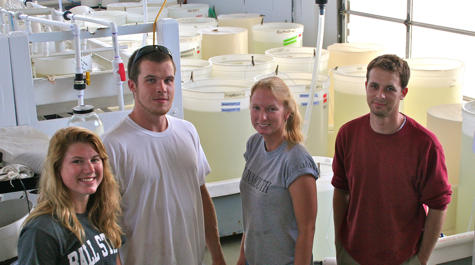

Current trainees are Elisabeth Bloom of Hayes, Ben Clark of West Point, Tommy Camp of Williamsburg, and Lisa Domalewski of Virginia Beach. The group ranges from 18- to 25-years old, and includes two college biology majors, a “life-long naturalist,” and a recent high-school graduate.

A 2008 survey by the Sea Grant Marine Advisory Program at VIMS shows a steady growth of oyster aquaculture in Virginia as watermen shift from the traditional planting of “shell on bottom” to farming using cages, racks, and floats. The number of farmed oysters nearly tripled between 2005 and 2006, and growers predicted a 33% increase during the most recent growing season, which would bring the number of farmed oysters to 25,000,000. There was a 6-fold increase in sales of farmed oysters by Virginia growers between 2005 and 2007 (from 843,000 to 4.8 million), and growers expected sales of farmed oysters to reach 7.3 million in 2008.

Although the survey shows that employment figures for Virginia’s oyster aquaculture industry declined between 2006 and 2007, Allen expects job numbers to resume their upward climb as the market grows and hatchery capacity increases. A shortage of oyster seed from existing hatcheries currently limits the growth of aquaculture in the Commonwealth.

During the six-month OAT program, the four trainees will work with VIMS researchers to learn all aspects of oyster farming, from hatchery production to grow-out. Karen Hudson, Research Coordinator at ABC, says “participants will be learning and working alongside researchers during our oyster hatchery season from April to September. The program started with two-week rotations in each area of ABC: hatchery, algae culture, lab, and field.”

The trainees agree that the breadth of the program is one of its key strengths. Clark, a North Carolina native who comes from a family of commercial anglers, says “it’s eye-opening to see what goes on from start to finish.”

“The rotations give participants a sound understanding of all phases of the oyster lifecycle,” adds Hudson. That lifecycle is complex, beginning with free-swimming larvae that subsequently develop into “spat” after attaching to shell on the bottom. Spat grow through a juvenile “seed” stage to reach market size at around 18 to 24 months.

Bloom, who expects to enroll in Thomas Nelson Community College in biology this fall, has enjoyed watching the larvae develop into juveniles. “The experience has really raised my interest in oyster aquaculture,” she says.

Hudson notes that trainees concentrated on the first two phases of the life-cycle throughout the hatchery rotation. “They learned how to care for oyster larvae, grow the algae that oysters eat, and collect eggs and sperm for spawning. They also explored the differences between “cultch and cultchless” setting. (In cultch setting, larvae attach to whole oyster shells as “spat-on-shell.” In cultchless setting, they attach to sand-like bits of oyster shell, eventually outgrowing them to become individual oysters.)

Camp, a Williamsburg native and 2007 graduate of Radford University, found particular interest in the process of natural spawning. “Dr. Allen demonstrated this as an alternative method that some growers use,” says Camp. “Instead of stripping the oysters like we did in the lab, growers set up conditions so that adult oysters brought in from the field spawn naturally in the lab. It’s a much less invasive process.”

Once oyster spat develop fully, staff transfer them to the VIMS nursery and field sites where OAT trainees will focus on the latter phases of the oyster lifecycle. “Here they’ll learn various upwelling systems and how to care for larger spat,” says Hudson. Upwellers use pumps to provide spat with a constant flow of seawater and food.

In the field, trainees will learn the importance of seawater flow rates, sieve and bag sizes, and oyster seed sizes and densities. They will also learn field grow-out methods, such as “rack and bag.” Trips to commercial facilities will acquaint the trainees with alternative grow-out methods.

It’s these field activities that Domalewski finds most appealing. Domalewski, who has a degree in Biology from ODU, says she’d like to “pursue the more hands-on aspects of aquaculture, with an eye toward oyster restoration.” Aquaculture, especially hatchery operations, are essential for restoration activities with native oysters in the Bay.

During the laboratory rotation, participants will use a technique called flow cytometry to identify if an oyster is fertile or sterile. Allen pioneered the genetic technique that imbues sterility; many growers prefer sterile oysters because these animals can divert energy from reproduction to growth, allowing them to reach market size before succumbing to the diseases that have decimated the Bay’s population of wild oysters.

Trainees will broaden their experiences by training with other groups, such as the Chesapeake Bay Foundation, where they can learn about oyster culture in the context of restoration and spat-on-shell production. Training opportunities also occur farther afield. OAT trainees recently visited Martinsville to experience tilapia culture, and future rotations are scheduled at the Haskin Shellfish Research Lab at Rutgers University in New Jersey and at the Horn Point hatchery at the University of Maryland.

By exposing trainees to various styles of aquaculture, the program hopes to give a broad perspective and appreciation for flexibility in methods of culture. “Growing oysters for research is not necessarily the modus operandi of commercial producers,” says Allen. “By the end of the program, trainees will have a broad understanding of oyster aquaculture and will have gained the skills needed to perform tasks in both oyster hatchery and field operations.

Allen notes that the program also benefits his own research operations by "providing seasonal help for the busiest time of the year in the VIMS research hatchery."